The Lark is a full carbon downhill bicycle prototype with a high-pivot design and uniquely modular drivetrain. Completely developed in Sweden by Huldr bikes. This is the designer Artur Adson's story about development.

Design

I was involved in the development of several prototypes for Huldr, responsible for the overall construction and applied composite design for manufacturing. The Lark was designed together with industrial designer Daniel Manfredsson and professional downhill rider Tim Hedman. My focus was on the overall product requirements and specific design features such as the modular seat mount with shock window, drivetrain mount and the compact linkage design.

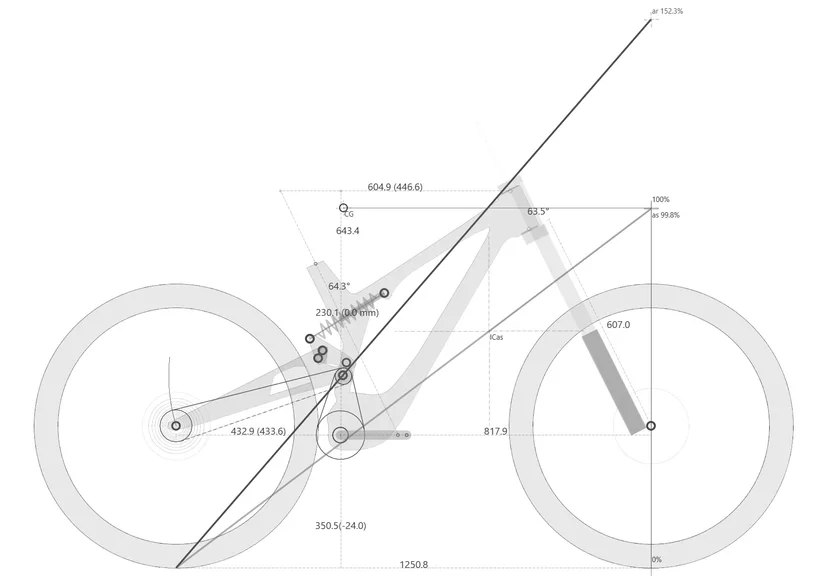

Geometry

The Lark concept features a dual chain high-pivot design, meaning that the swingarm point of rotation is above the rear axle. The rear wheel moves slightly rearward during shock compression, as if it’s being pulled by the obstacle. This allows the rear wheel to clear obstacles smoother and faster.

Linkage design

Another key feature is the compact suspension linkage. On most downhill and mountain bikes the shock is placed inside the triangular open space of the frame. On the Lark we wanted to free up this space for a large battery pack. The compact design achieves this without compromising the responsive and progressive shock characteristics expected from a high-end downhill bike.

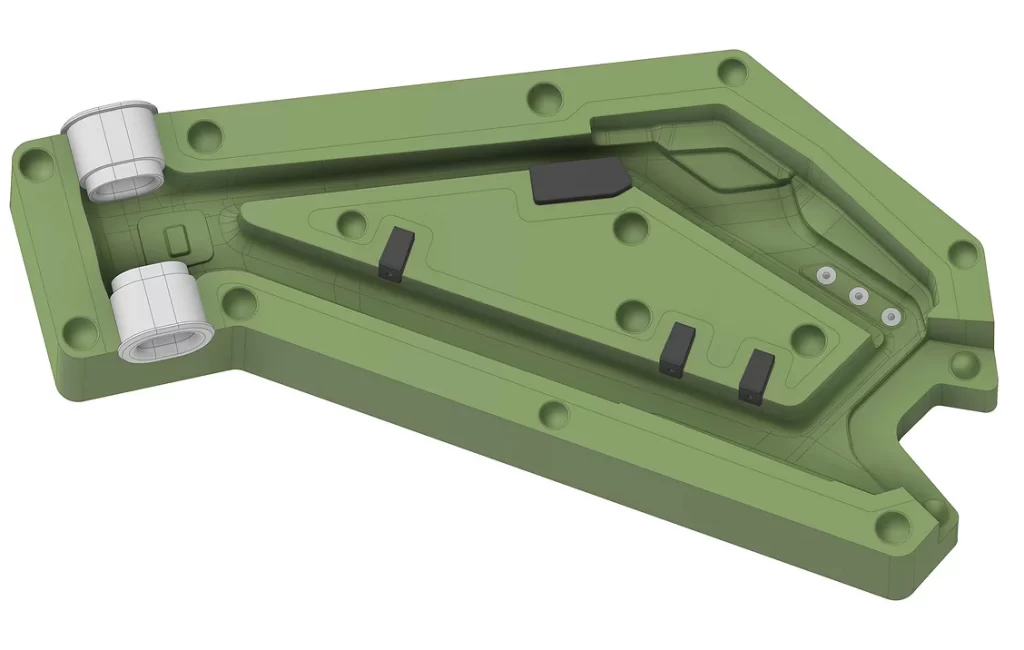

Modular drivetrain

The frame can be configured with 3 different drivetrains thanks to a uniquely modular adapter system, ranging from an enduro bicycle with a manual gearbox to a high-power ultra-light motorcycle.

A 12-speed manual gearbox that allows you to shift gears without pedaling. Since the gears are all internal, the chainpath remains the same throughout the gears. As a result there is much less wear on the drivetrain system.

1000 W motor with 120 Nm. Carefully selected and outperforms all other well-known e-bike motors from Bosch, Shimano and Bafang. With 1000 W power it is considered a moped or S-Pedelec with a speed limited to 45 km/h (+60km/h unlimited).

This is the most powerful option with up to 5000 W peak power. It can reach a top speed of over 70km/h with the Sonceboz and is considered an ultra-light motorcycle.